ESG/CSR

Quality Assurance Initiatives

Quality Assurance

Quality Policy

We aim to contribute to society by supplying our customers with products backed by world-class technology and by raising customer satisfaction to the highest level, thereby improving the company's profits and the welfare of our employees. To this end, we set quality targets to constantly promote technological and operational innovation in every process of our work, and by implementing a "management cycle," we aim to improve the quality of not only our products but also our operations, and to make continuous improvements, as part of our "Meiko Quality Policy." Naturally, we also meet legal and regulatory requirements.

Ensuring quality that meets customer expectations and instills confidence

October 23, 2017

President and CEO

Yuichiro Naya

Initiatives to meet customer requirements

M-QMS (Meiko Quality Management System)

Meiko Group's products are used by a wide range of electronic equipment-related customers, but the quality of automotive-related products is becoming increasingly important, and in addition to our ISO9001:2015-based quality management system, we have adopted the Automotive Process Approach (APA), a mandatory requirement of IATF16949 (International Automotive Task Force standard). We also conduct analysis with an emphasis on customer-oriented processes (COP), and meet customer requirements through quality verification at the design and development stages, global quality assurance activities, and external process management.

We are also working to improve quality through continuous improvements to our quality management system.

Objective evaluation to ensure safety and security (design review)

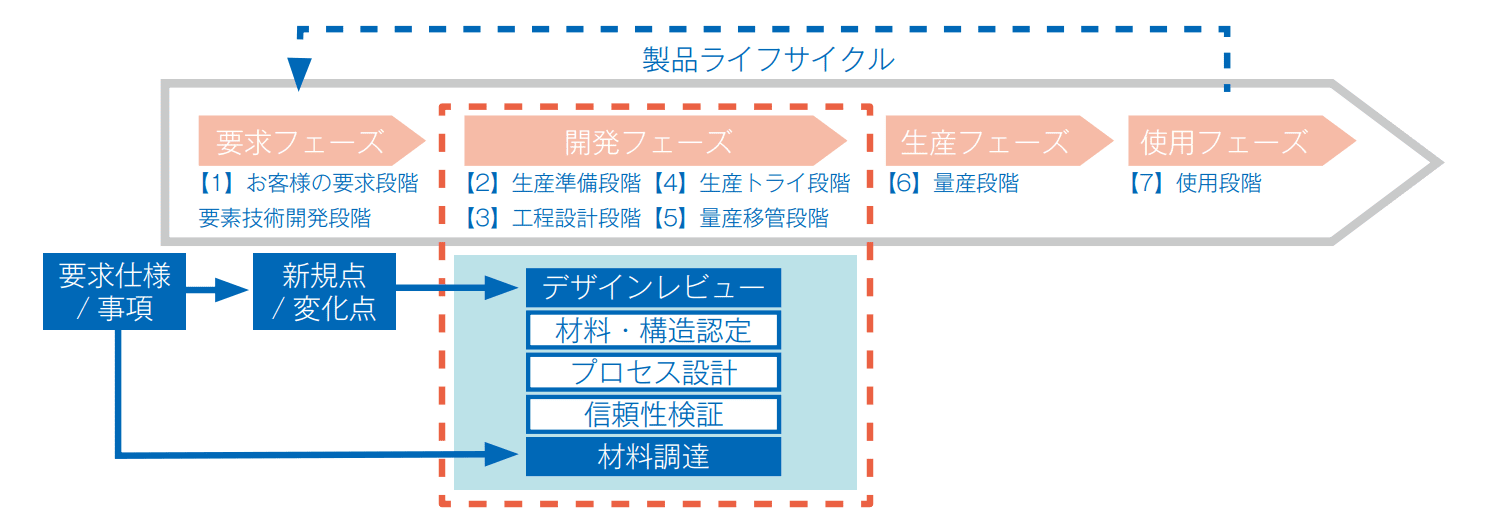

During the development and design stages of new products, we conduct design reviews (DR) to ensure design quality before mass production. Meiko Group's DR system sets ranks based on risk assessment and systematizes each process in the development phase for each rank.

At the implementation stage, the production design, engineering, and quality assurance departments are primarily responsible for verifying changes and past troubles, and verifying the product and manufacturing feasibility against risks to make preventative improvements, including preventing recurrence, and to achieve requirements.

Quality of Procured Products (Quality Initiatives for External Processes)

At the implementation stage, the production design, engineering, and quality assurance departments are primarily responsible for verifying changes and past troubles, and verifying the product and manufacturing feasibility against risks to make preventative improvements, including preventing recurrence, and to achieve requirements.