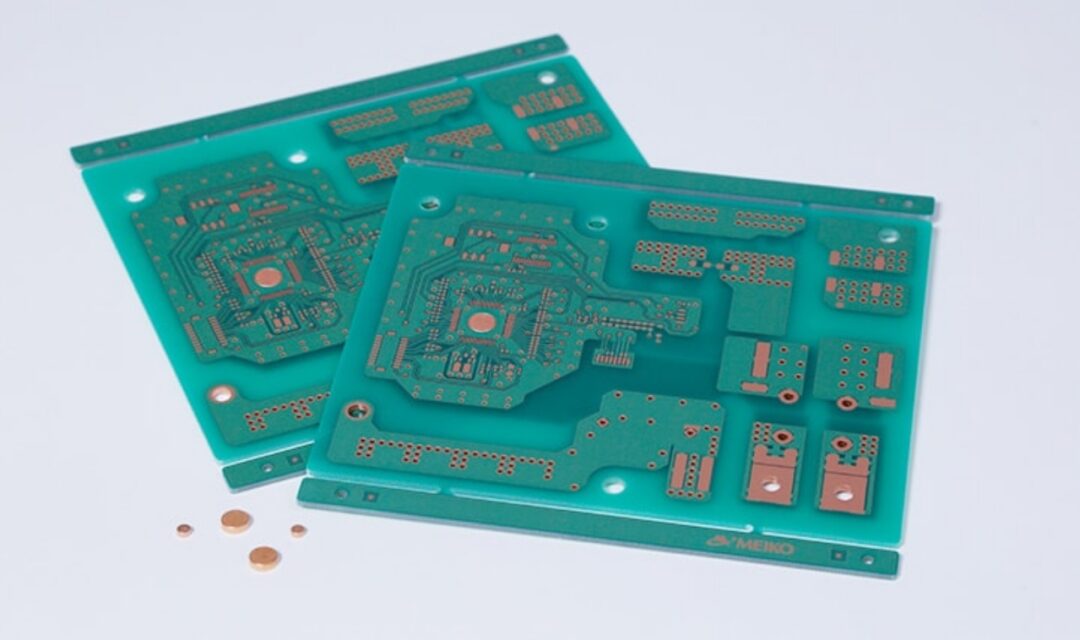

Copper Inlay PCBs

Copper Inlay PCBss are useful for heat dissipation of heat-generating components. Heat dissipation is achieved by pressing a copper block (copper inlay) directly under the heat-generating component. Because heat is not dissipated over the entire board, there is the same degree of freedom in wiring as with a normal multi-layer through-hole board. Components can also be mounted on both sides of the board. (The copper inlay itself does not have reliable conductivity.)

Characteristics of copper inlay substrate

- Multi-layer boards are possible, which is difficult with metal-based boards

- The optimum copper inlay size can be selected according to the amount of heat generated.

Main uses

-

In-vehicle electric power steering (EPS)

-

In-vehicle electronic control unit (ECU)

-

Automotive LED headlamps

Contact About the productInquiry

In addition to major corporate clients, we also serve universities, research institutes,

We also accept consultations from venture companies.

We also accept one-off orders from design companies and parts trading companies,

Please feel free to contact us for technical advice.